All about Mooring Ropes India

Wiki Article

The Best Strategy To Use For Mooring Ropes India

Table of ContentsNot known Facts About Mooring Ropes IndiaThe 9-Minute Rule for Mooring Ropes IndiaWhat Does Mooring Ropes India Mean?All about Mooring Ropes IndiaThe 3-Minute Rule for Mooring Ropes IndiaNot known Details About Mooring Ropes India

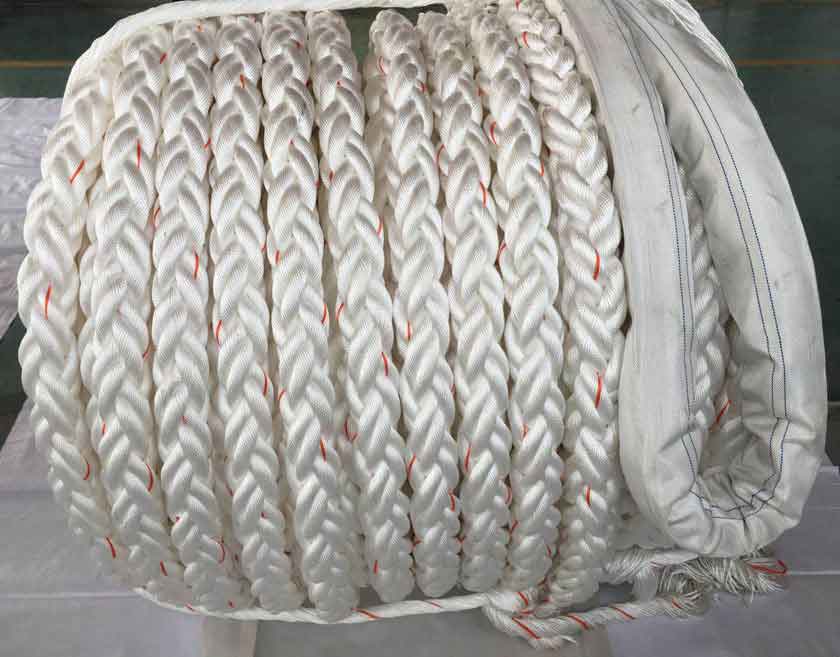

, likewise referred to as or, are ropes or lines used to safeguard a vessel to a dock or to an additional vessel. Anchoring ropes play a vital function in maintaining a vessel safely secured to a dock or an additional vessel, avoiding damage to both the vessel and its surroundings. This essay will certainly provide a review of mooring ropes, including the kinds of ropes offered, factors to take into consideration when picking ropes, maintenance strategies, linking methods, security considerations, and the importance of mooring ropes in marine operations.They are resistant to abrasion, UV rays, and water absorption, however they tend to stretch over time and are vulnerable to mold otherwise dried effectively - Mooring Ropes India. Polyester ropes are solid, durable, and immune to abrasion, UV rays, and water absorption. They have much less stretch than nylon ropes and are less prone to mildew, making them a preferred option for lasting mooring applications

They are resistant to abrasion and UV rays but are vulnerable to water absorption and mildew. They are much less generally utilized for mooring yet are still a viable choice in particular applications. The toughness of the mooring rope ought to appropriate for the weight and dimension of the vessel being safeguarded.

The Basic Principles Of Mooring Ropes India

Anchoring ropes need to be saved in an amazing, dry, and well-ventilated location when not in usage. Prevent saving ropes in straight sunshine or damp areas, as this can lead to rot or mold.

This involves covering the rope around the cleat and going across completion of the rope over itself, then making a figure-eight with the rope around the cleat horns and finishing with a fifty percent hitch to safeguard the rope in place (Mooring Ropes India). The bowline knot is a flexible knot that can be made use of to develop a loophole at the end of a rope for linking to a cleat or various other anchor point

Not known Incorrect Statements About Mooring Ropes India

The round turn and two-half drawbacks knot is a solid and safe and secure approach for linking a rope to a loading or various other anchor factor. This entails making a rounded turn around the anchor factor, after that making 2 half drawbacks around the standing component of the rope. The figure-eight knot is an easy and reliable knot that can be utilized to create a stopper knot at the end of a rope or to sign up with 2 ropes together.It is very important to keep track of weather condition conditions and prevent handling ropes in unsafe problems. In case of an emergency such as an abrupt storm or equipment failing, it is essential to have emergency treatments in position for quickly launching mooring ropes and securing the vessel. This might include having actually a designated individual in charge of releasing the ropes, or having emergency release devices set up on the mooring imp source system.

When choosing mooring ropes, it is necessary to think about variables such as strength, abrasion resistance, UV resistance, water absorption, and elasticity. Appropriate upkeep of mooring ropes involves regular examination, cleansing, and storage. Methods for connecting mooring ropes include the cleat hitch, bowline knot, round turn and two fifty percent hitches, and figure-eight knot.

An Unbiased View of Mooring Ropes India

is the successor to Nylon, Polyester still gives extremely good stretch residential properties. Polyester provides fantastic resistance against abrasion, is less influenced by UV radiation, does not shed toughness when damp and is extremely soft to the touch. SK75 and SK78 fibers are a lot more than twice as solid as Polyester in the same diameter but much less than half the weight.

For that reason our Dyneema mooring lines are shielded with a polyester cover. Simple Dyneema will soak up no water and can even drift, making it terrific for tow or ground lines. The major drawback to Dyneema is the lack of stretch, when utilizing Dyneema as a mooring line we advise using polyester loops as cots.

5 Easy Facts About Mooring Ropes India Described

had actually obtained a contract to provide deepwater mooring rope over 63,000 m for the Covering Appomattox task, which is the lengthiest rope meterage for a solitary deepwater mooring agreement.

Mooring is a complex operation. Whether protecting a huge liquified gas (LNG) Check Out Your URL carrier in the heat of the Middle East, or mooring a products vessel in freezing Arctic problems, there are a variety of crucial elements drivers need to consider when choosing fiber for mooring lines. Stress fatigue: Even when anchored, wind, waves, and currents maintain a ship in constant activity.

Mooring Ropes India Can Be Fun For Anyone

Abrasion resistance: Whether being gone through a fairlead or over a capstan, mooring lines are subject to severe rough forces that can minimize solution life. Ropes made with Dyneema SK78 have a proven abrasion lifetime that is 4x longer than that of common HMPE lines, which can be even more enhanced by applying a proprietary layer.Report this wiki page